Roasted coffee beans(powder) packaging is the most variety of coffee packaging. Because coffee is naturally produced after roasting, it is easy to directly produce packaging and packaging and contact with air, which will lead to oxidation of the oil in the coffee and the inactive components of the pump, resulting in a decrease in quality. Therefore, the packaging of coffee beans (powder) is very important.

Sort of Packing

There are many types of coffee packaging and various materials. Please don't think that coffee packaging is just what kind of colorful small bags you have usually used. In fact, the world of coffee packaging is very exciting. Here is a brief introduction to the knowledge of coffee packaging.

According to the form of coffee supply, coffee packaging can be basically divided into three categories: green bean export packaging, roasted coffee beans (powder) packaging, and instant coffee packaging.

Export packaging of raw beans

Raw beans are generally packed in sacks. Different coffee producing countries in the world usually use 70 kg or 69 kg sacks when exporting coffee beans (only Hawaiian coffee is packaged in 100 pounds). In addition to printing the names of the country and its coffee organization, coffee production unit, and producing area on the coffee sacks, the most typical patterns of the country will also be printed on the sacks. These seemingly ordinary commodity sacks, in the opinion of coffee fans , Has become a footnote to interpret the background of coffee culture. It has even become a collection of many coffee fans, and this type of packaging can be called the initial packaging of coffee.

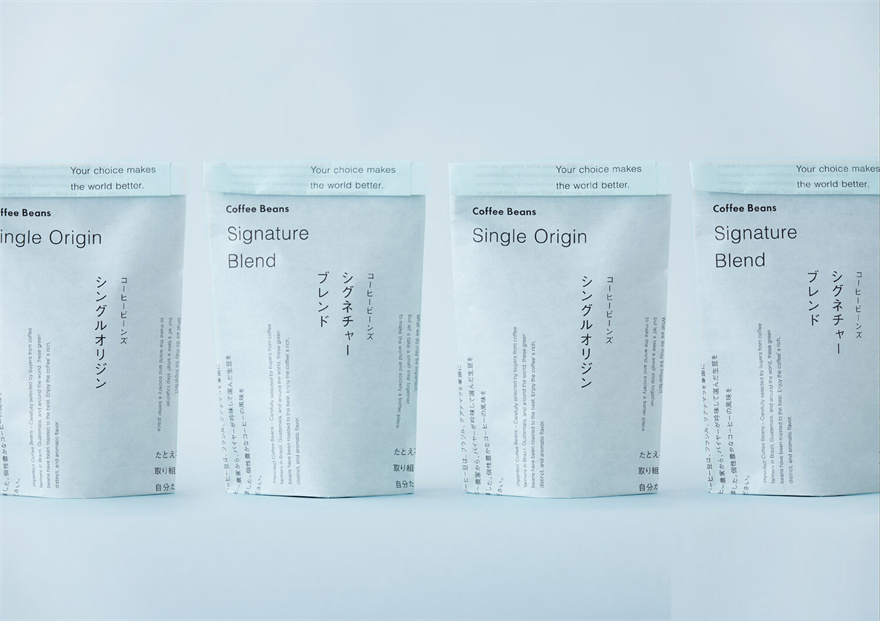

Roasted coffee beans (powder) packaging

Generally divided into packaged and canned.

(1). Bagged:

Bagged packaging is generally divided into: non-airtight packaging, vacuum packaging, one-way valve packaging, and pressurized packaging.

Non-airtight packaging:

In fact, it is a temporary packaging and is only used for short-term storage.

Vacuum packaging:

The roasted coffee beans need to be placed for a period of time before packaging to prevent carbon dioxide from damaging the packaging. Such packaging can generally be stored for about 10 weeks.

One-way valve packaging:

Adding a one-way valve to the packaging bag allows the carbon dioxide generated to be eliminated but prevents the entry of external air, ensuring that the coffee beans are not oxidized but cannot prevent the loss of aroma. This type of packaging can be stored for up to 6 months. Some coffees are packaged with vent holes, that is, only vent holes are made on the packaging bag without a one-way valve, so that once the carbon dioxide produced by the coffee beans is emptied, outside air will enter the bag and cause oxidation, so it is stored Time is greatly reduced.

Pressurized packaging:

After the coffee beans are roasted, they are vacuum-packed and sealed with inert gas. This type of packaging can ensure that the coffee beans are not oxidized, while ensuring that the aroma will not be lost and have sufficient strength to ensure that the packaging will not be damaged by air pressure and can be stored for up to Two years.

(2). Canned:

The cans are generally metal and glass, and they are equipped with plastic lids for easy airtightness.

Instant coffee packaging

The packaging of instant coffee is much simpler. Generally, small sealed packaging bags or rollstock film are used, mainly in long strips, and outer packaging boxes are also available. Of course, there are also some canned instant coffee supplies on the market.

Materials

Different types of coffee packaging have different materials. Generally, the raw bean export packaging material is simpler than the ordinary sack material. Instant coffee packaging also has no special material requirements, and basically uses general food packaging materials. The packaging of coffee beans (powder) generally adopts opaque plastic composite materials and environmentally friendly kraft paper composite materials due to the requirements of anti-oxidation.

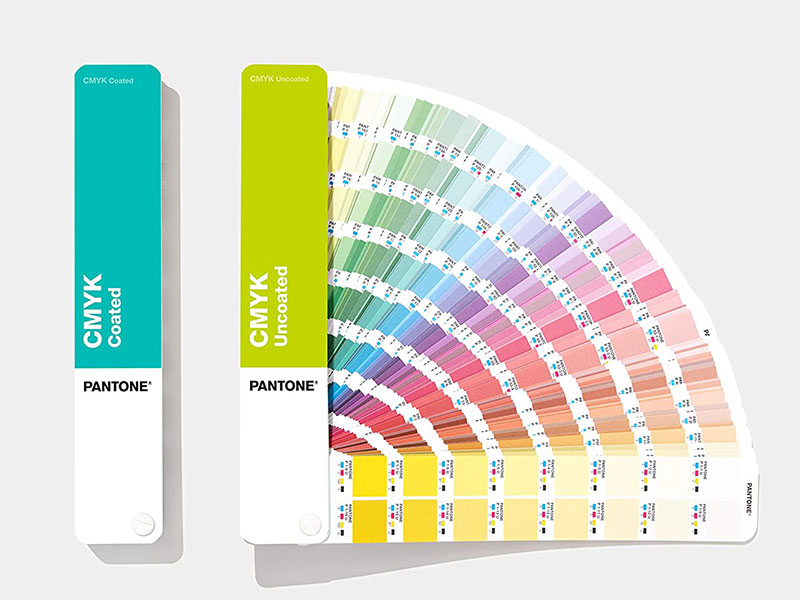

Packaging color

The color of coffee packaging also has certain rules. According to the conventions formed in the industry, the color of finished coffee packaging reflects the characteristics of coffee to a certain extent:

The red-packaged coffee generally has a thicker taste, which can make the drinker wake up quickly from the good dreams of last night;

Coffee in black packaging belongs to high-quality small fruit coffee;

Coffee in golden packaging symbolizes wealth and shows that it is the best in coffee;

Blue-packaged coffee is generally "decaffeinated" coffee.

Coffee is one of the world's three largest soft drinks and the second most traded product in the world after oil. Its popularity is evident. The coffee culture contained in its packaging is also very attractive because of its long-term accumulation.

If you need update you coffee brand packaging, please feel free contact us: