Did you know that the daily coffee consumption has been up to a 20-year high among United States adults in 2024? And now, the data continues to rise. Besides, In January 2024, specialty coffee consumption hit 45%! As you can imagine, the competition for coffee beans is quite fierce. In order to ensure the quality of coffee and gain a better advantage in the coffee industry, the choice of coffee packaging bags is particularly important. Coffee packaging world boils down to two main contenders: the versatile coffee bag and the classic coffee can. Let's go into the world of coffee packaging to uncover the best packaging solution for keeping your coffee fresher and more suitable.

What Affects your Perfect Coffee Beans?

Before we dive into packaging solutions for coffee bags and cans, let's understand what we're trying to protect coffee from. During roasting, the Maillard reaction transforms the green coffee beans into the flavorful, aromatic coffee we enjoy. After roasting, coffee beans are vulnerable to several environmental factors that can quickly degrade their flavor and aroma:

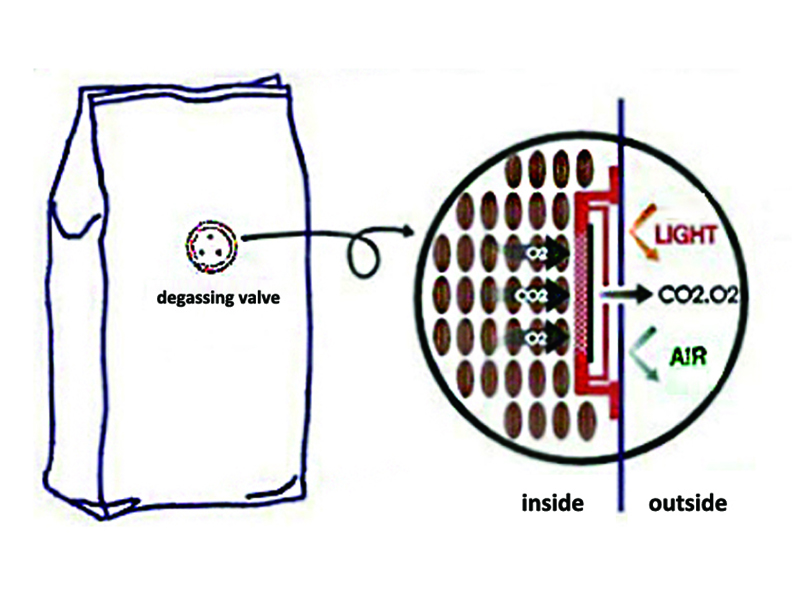

Oxygen - Oxidation is a coffee bean's worst enemy. It causes the oils within the bean to go rancid, resulting in a stale, cardboard-like taste.

Moisture - Moisture leads to mold growth, staleness, and ultimately, undrinkable coffee.

Light - Exposure to UV light can break down essential oils and degrade the coffee's flavor profile.

Heat - Excessive heat accelerates the staling process.

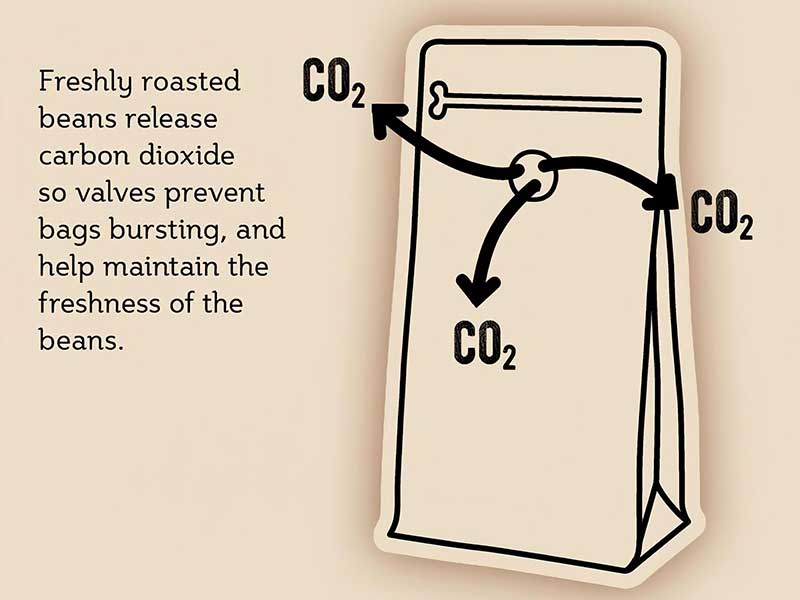

Aroma Loss - Coffee beans release volatile aromatic compounds over time, and poorly sealed packaging allows these compounds to escape, diminishing the coffee's fragrance and flavor.

Coffee Bags: A Versatile Option

- Pros

Cost-Effectiveness - With the rise of digital printing, flexible packaging bags has been generally become the first choice for most coffee beans business. As we all known, No MOQ, high quantity and fast lead time are the biggest advantage for digital printing. Besides, Mylar bags are excellent for coffee beans storage, which offer protection against moisture, oxygen, light, and pests. For small business or the development of new products, the lower minimum order quantity can reduce inventory pressure and save a lot of money overall. In addition, if the quantity is large, gravure printing, that is rotogravure also has obvious advantages of the cost. Not to mention, the bags weigh much less than cans, saving a ton of money on shipping costs.

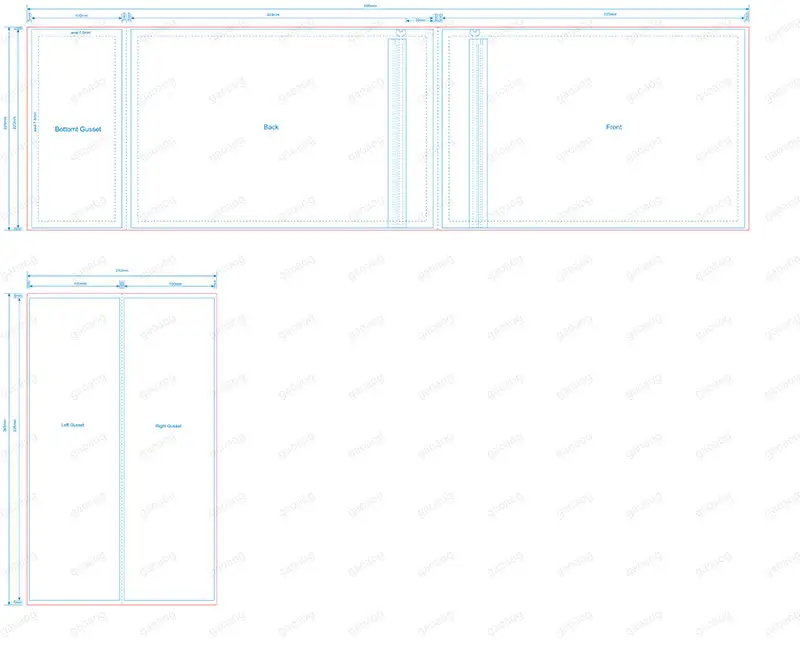

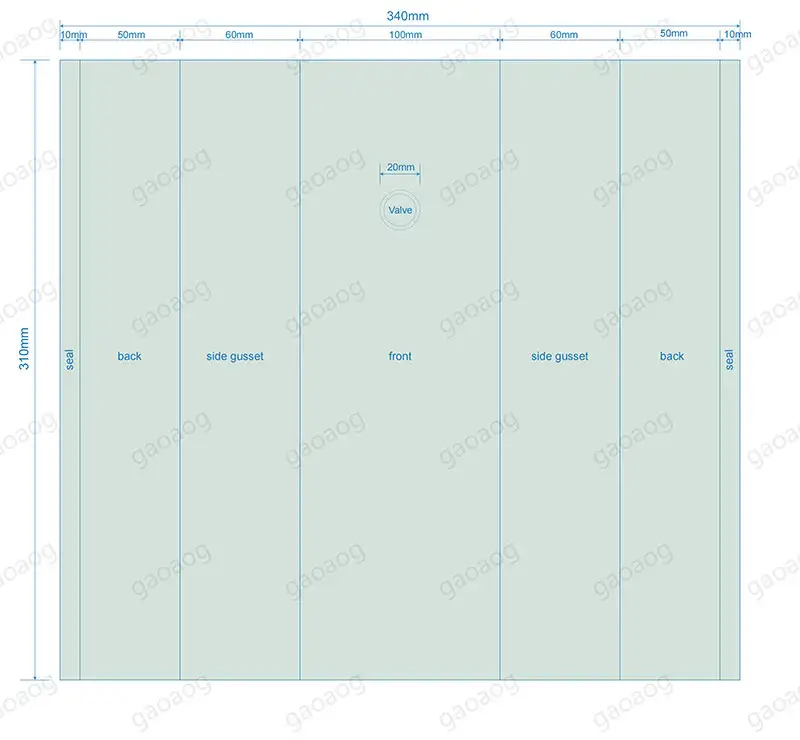

Design Flexibility - There are many types of coffee packaging, such as instant coffee bag for freeze-dried coffee powder, roll stock or sachets for rice coffee, drip coffee bag (three side seal bags/ filter bag) for drip coffee, coffee brewer bag (spout bags) for cold brew coffee, coffee packaging pouches (stand up pouches, flat bottom coffee bag, quad seal coffee bag and side gusset coffee bag) for coffee beans or coffee powder, and coffee bag labels/ stickers on the blank coffee bags. Besides, the size is fully customized, it can pack any grams you want with no limited. In addition, the bags have more area design to maximize the brand image and increase customer interest.

Sustainable Materials - Generally, all plastic bags can be recycled. If you need 100% recyclable packaging, professional recyclable materials are essential. Like mono material like brown craft paper, 100% polyethylene (PE) and polyester (PET), Post-Consumer Recycled (PCR), BOPP films and high density polyethylene (HDPE). In addition, biodegradable coffee packaging bags is also popular in Europe and Australia now, it needs to used polylactic acid (PLA) materials. Using theses eco friendly coffee packaging bags can make the world greener.

- Cons

Lower Barrier Protection - Compared with tin-coated steel or aluminum cans, the protection of bags is indeed not as strong as that of cans. If they encounter sharp blades or strong impacts, the bags are likely to be damaged. But in general, the bag is made of 4 layers of material (MOPP/PET/AL/PE), which is about 140mic and the high barrier films and proper sealing are sufficient.

Coffee Cans: The Premium Choice

- Pros

Superior Protection - Coffee cans packaging (coffee tin packaging) usually made by tin-coated steel or aluminum, which can keep the coffee in a dark, dry place and out of the reach of the UV light and in the ambient temperature, which helps to preserve the tea and coffee for a long time.

Durability - Cans protect the coffee inside and against any damage and helps to preserve its primary form during loading and transportation of the product. Some business focus on maintaining the integrity of specialty coffee, which is indeed an important decision to avoid the loss of gourmet coffee.

- Cons

Higher Cost - With the same capacity, the price of a can is several times or even more than that of a bag, and the shipping cost will also double due to its heavier weight.

Limited Design Flexibility - Cans are usually round or square, and after the display surface is laid flat, there is only one rectangle or four sides that can be designed.

BPA Concerns - Some cans may contain BPA, a chemical that can leach into the coffee, especially at high temperatures. It would be detrimental to consumers’ health.

In conclusion

Coffee bags and cans have their own advantages and disadvantages. Coffee bags still the best choice for most coffee business. No matter you want to pack coffee powders, all kinds of beans, cold crew coffee, etc., the bags are always be your suitable choice. Coffee bean bag with all kinds of coffee bag valves and zippers can perfect your packaging and keep your coffee beans fresher.

Now, contact us, gaoaog, an experience coffee bag supplier, to discuss your specific coffee bag design ideas . We offer a free guide or coffee bag mockup for coffee packaging. Let’s start to custom coffee bag!