Design drawings become real objects by digital printing for small order

Today we will talk about the most of customers’ questions in detail, how to turn the designs into a real objects? How does the designs become a real packaging bag.

At first we need confirm the Bag’s type/ Size/ Materials/ Thickness

Custom Flexible packaging Bag’s type:

The all can by digital printing such as lay flat pouch (Three side heat seal bag, pillow pouch); stand up pouch(with window, with normally zipper, with valve, easy tear notch zipper, child resistant zipper, Velcro zipper, double zipper); flat bottom pouch; Side gusset bag; shrink film; rollstock; Spout pouch;Custom shape flexible packaging pouch;

Custom flexible packaging Bag’s size:

we need confirm what will packing in the packaging bag, and how many gram or ml will inside? So we can double check the size and if customers not sure the size, we can give some suggestions if they need;

Custom flexible packging bag’s Materials:

It will depend on the function you need, and different products has different features, such as if for liquid or wet wipes packaging the inside layer we need use the liquid PE or white PE material, and for oil we need oil PE material, and for frozen food we need frozen PE material, and for biscuits generally inside layer use CPP material, and the surface if you need matte or glossy or the other effect, the surface layer we need use Matte BOPP or BOPP or PET or NY or soft touch film material, and if you need sliver or products need avoid light we need use aluminum foil material in middle layer; all the materials of the bag’s its not simple as it seems;

Custom flexible packaging Bag’s Thickness:

Generally from 30-180mic; it will depend on the bag’s type and customer’s requirements;

After we confirm the bag’s size materials thickness, and confirm the quantity for quotation, when you confirm the price and pay deposit, and send us the artwork, we will start production, at first we will adjust the artwork for color printing and will send you for reconfirm,after we approved the artwork, we will start color printing on our HP indigo 20000 digital printing press;

Artwork approved start color printing- Checking

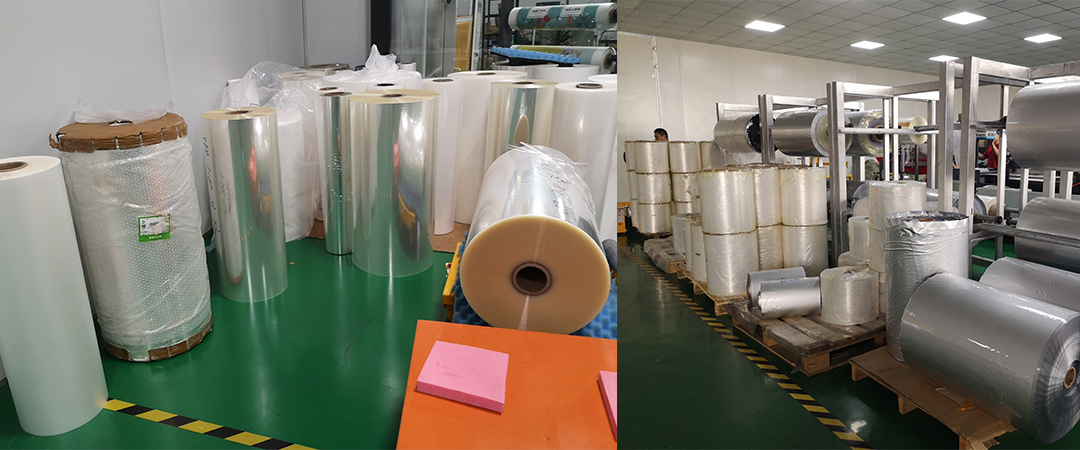

laminating - laminating the raw materials( such as printing inside PET/VMPET/PE; )

bakery- checking- ( after laminate the materials need put them in the drying (curing barn) for bakery about 12-36hours);

Cutting- after finished bakery , we need took them out and cutting in roll;

Making bag- Then we can take the roll stock in the machine and start making bag;

Checking Qty& Quality- when making bag the machine also checking the quantity and workers must check the quality for the packaging bag;

Packing in Box- generally 50pcs a bundle and will packing as the customer’s requirements;

Shipping in you hand- After confirmed the actually weight for the goods and confirmed the freight fee, we will arrange shipping , if by express dhl or fedex about 3-7days will in your hand.

It’s very simple, the designs from you and leave the professional stuff to us; 200pcs start customized; delivery in 3-7days; high quality color printing; No need Cylinder fee;